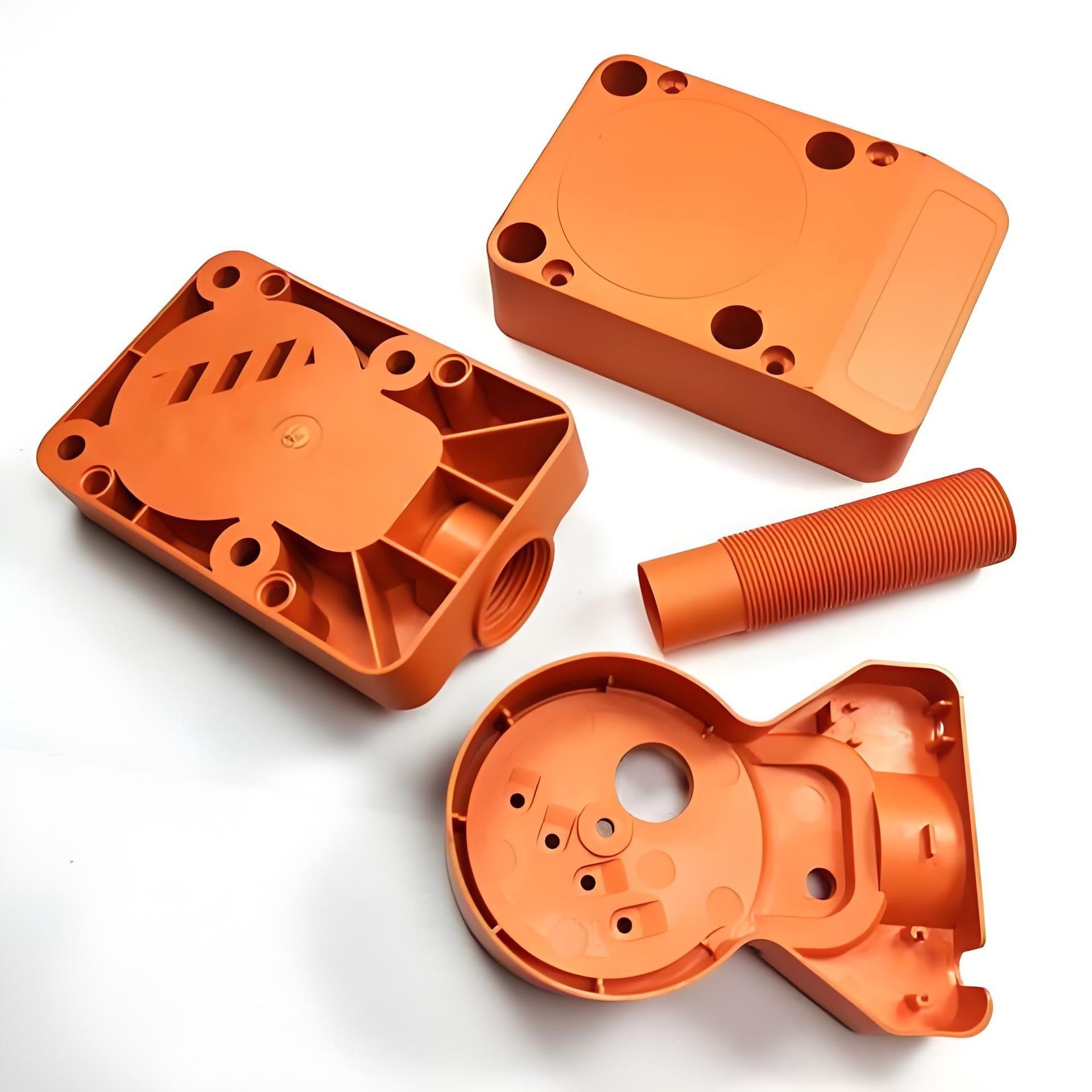

When you want to do a trial production for your plastic or rubber parts, silicone molding is one of the more efficient ways.

We provide time- and cost-saving silicone molding service to help our clients succeed in their industries.

The advantages of silicone molds are mainly reflected in their physical and chemical properties, including high temperature resistance, corrosion resistance, strong tear resistance, high simulation precision, good chemical stability, non-toxic and non-corrosive, good fluidity, and rapid molding.

Physical property advantages :

Silicone molds are resistant to high temperature, corrosion, and tear. These characteristics enable silicone molds to withstand extreme working environments and extend their service life.

Silicone molds have high simulation precision and are suitable for making various parts, which can ensure the fineness and authenticity of the products.

Chemical property advantages :

Silicone molds have good chemical stability and will not easily undergo chemical reactions, ensuring the long-term stability of the mold .

Silicone molds are non-toxic and non-corrosive, safe for the environment and human body, and suitable for the production of food-grade products.

Operation and use advantages:

Silicone molds have good fluidity and operability, can be quickly vulcanized at room temperature, and are easy to operate 45.

Silicone molds have good demolding properties and can be demolded quickly, reducing production time and improving production efficiency.

Silicone molds are made quickly and can generally be completed within 20 hours, greatly shortening the production cycle.

All copyright reserved @ Shenzhen ChicTao Trading Co., Ltd.

Powered by WL Co.