BLOG

By SL

•

September 6, 2024

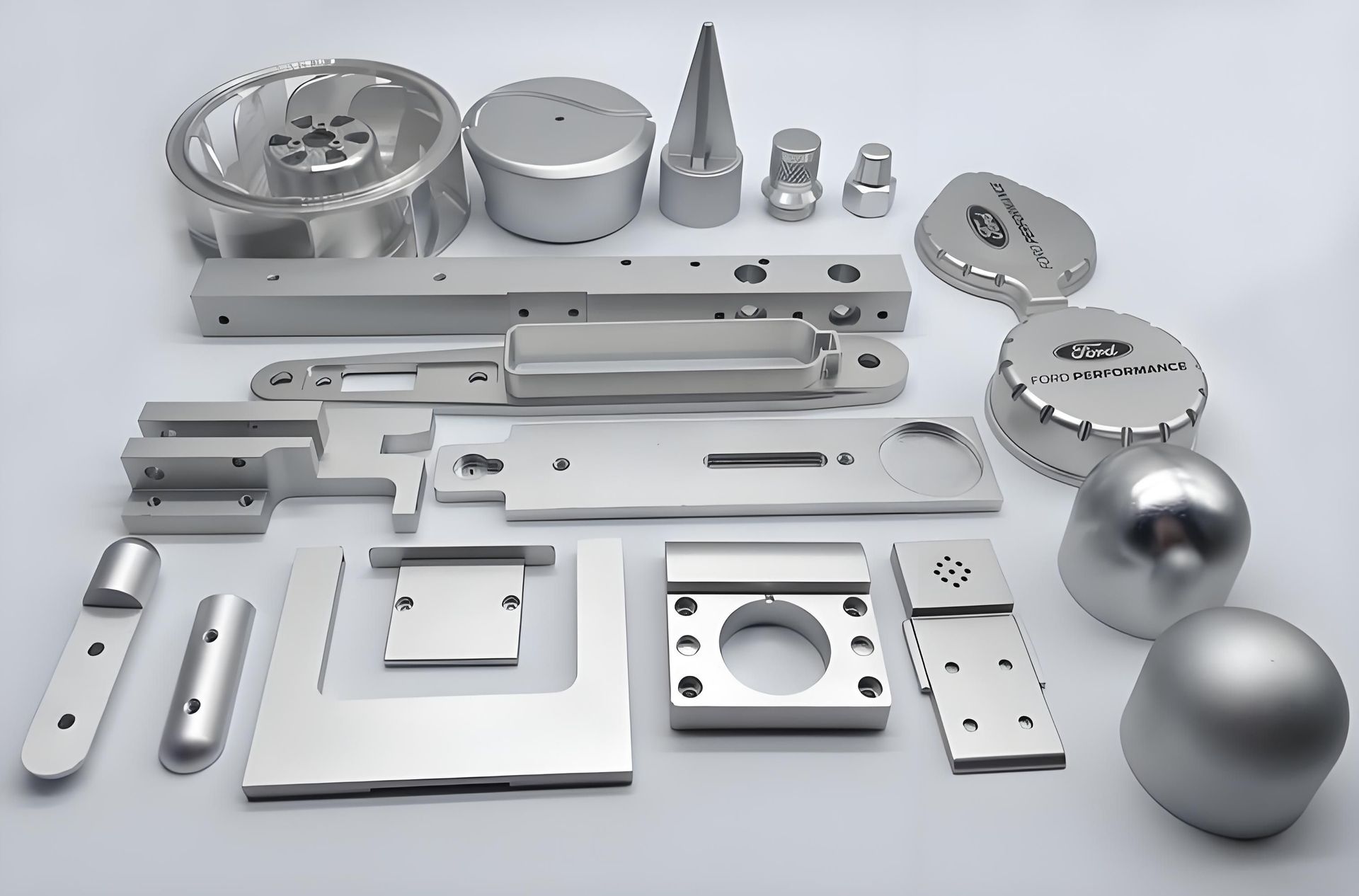

What is CNC? Keywords: Terminology, history and applicable materials By definition, CNC (Computerized Numerical Control) means controlling a machine tool or other device automatically by a computer instead of direct manipulation by an operator. Machine tools, on the other hand, use different processes like milling or turning for a piece of raw material to produce a ready workpiece – this is often called discrete manufacturing. It’s notable that the first NC-machines in 1940s and 1950s used paper tape or punched cards to control the motion. ‘NC’ turned ‘CNC’ only after computers were introduced as controllers in the 1960s. The programming language that turns an NC-program – information – into precise machine tool movements is called G-code. At first, most of of the CNC machines were custom-built for a certain part manufacturing needs, like in the below picture, although general purpose machinery were also produced for turning or drilling processes for example. Since the 1990s general purpose CNC machining centers, suitable for certain processes and part diameters (e.g. 4-axis milling machine with a table of 800x800mm) have evolved tremendously and taken over majority of the markets. In principle CNC machines can be used on any material from metal to composites, wood, plastics and so on. Although Fastems has worked with customers in all of mentioned material domains, this page is focused on metals and composites. The main CNC machining processes CNC as such can be applied in a huge variety of manufacturing processes and machinery. In this page we focus on machining operations that can be identified by their production of chips. This means the processes are substractive by nature and the equipment involved are oftentimes called cutting machine tools. Referring to the page title, CNC machining can be defined as automatically and digitally controlled machining processes. Main machining processes include: Milling, where the spindle rotates removing material. Turning, where the cylindrical workpiece rotates while spindle is fixed removing the material Drilling, where a hole is cut into the workpiece Grinding, where a rolling, abrasive wheel removes light amounts of material Sawing where material is cut (into parts) with a blade. Finishing operations Filing that is about light amounts of material removing, combining grinding and sawing and is used mostly in deburring Polishing and brushing, where a smooth or shiny surface is created with abrasive process. The main types of CNC machines Given the machining operations context set above, the most typical CNC machine tools are: 3-, 4- and 5-axis milling machines, sometimes also called machining centers Turning machines Multitasking machines: turn-mills and mill-turns that combine a milling spindle and workholding for turning operations. Grinding and sawing machines When discussing the finishing and other supportive processes for machining, one can also add to the list various machinery or cells that are digitally and automatically controlled via PLC (programmable logic controller) such as deburring with a robot or can be considered to be CNC machines such as a marking machine. These can include: Deburring with robot Sanding with robot Polishing with robot Washing machines Marking machines Measuring machines CNC machining automation Automating your CNC machines is a vast topic. This section begins the journey by explaining the typical activities offering automation potential. Finally, an illustration combining the type of automation with machinery/process types is introduce summarizing this whole page. What activities can you automate? Automation simply means the reduction of human intervention to a process. Below you can see the two main categories of activities offering the most automation potential around CNC machines. The best practices on how automate them are disc usse d here . Automating production planning and resource management Orchestrating your people, machinery and IT-systems to work as one. In practice this means features like: Automated information flows between different data systems and machinery or cells. Proactively and constantly updating production plan based on production orders and their priorities Automatic fetching of orders from ERP Operator guidance to always take the right action at the right time Workpiece manufacturing ‘recipe’ handling Managing of (complex) production phasing within production process Proactive resource management vs production plan and reports of missing resources. Fixtures, pallets and grippers Raw materials NC-programs Cutting tools, tool data and off-sets Reporting and analytics Production and machinery KPIs such as utilization, OEE, availability… Order progress views Inventory / work-in-progress Production event history and traceability Automated documentation (paperless production) Automating physical movement and operations Automation hardware can replicate reproducible and stable processes with very high efficiency and accuracy. In practice this can mean activities like: Transfers of (zero-point) machining pallets to/from machine table. Automated fixture loading/unloading with a robot Direct transferring of workpieces to machine table or chuck Automated chuck adjustments or changes Gripper and tool changes in robots Tool transfers to tool magazines Workpiece movements to/from machining supportive processes like Deburring Washing Heat treatment Washing Marking Polishing Measuring Raw material management and transfers Semi-finished product management and transfers How to combine automation and CNC machines? The illustration below lists the typical (but certainly not all) CNC machining operations and machinery offering automation potential. Secondly, it shows what the required automation level implies for the automation system: It’s always possible automate the production planning and resource management activities – even without automation “hardware”! Example of such software is Fa stems’ WCO that is part of our Manufacturing Management S oftware ( MMS ) suite. If one is looking to automate the physical movement of workpieces, pallets, tools, raw materials and so on, then going for different pallet or part handling automation solutions is the right way. Please keep in mind tha t production planning and resource management features are just as important when talking about physical automation. See our solution finder to explore your options for e.g. 4-axis milling machines or turn-mill machines.

By WL

•

September 6, 2024

What is CNC Machining: Definition, Process, Purpose & More Keywords: CNC maching services, CNC machining center, CNC processing center, automated CNC machining, CNC milling, CNC grinding, CNC drilling, CNC routing The CNC machining process offers many advantages because it is automated and uses computer-controlled machine tools to fabricate parts from raw materials. The process can produce many different parts with varying levels of complexity. CNC machining is often used in the aerospace, automotive, and medical industries, where specific parts must meet stringent specifications and tolerances in manufacturing processes. CNC machining has made it possible to create objects a hundred times faster than a few decades ago. So what is CNC machining and how does it work? This article explores all you need to know about CNC machining, what it is, how it is done, different types and the benefits of the process. What is CNC Machining? CNC machining is a type of automated machining process that uses computer numeral control technology to shape an object or a part by removing material from a workpiece until the desired shape is achieved. CNC stands for Computer Numerical Control. It means utilizing computerized software to control how a machine moves and operates. It works by converting a digital model of a part into a sequence of computer instructions that control the actions of the machining tools to achieve the desired output CNC machining equipment works on a variety of parts, such as metals, metal alloys, wood, stone, and more. The size of machine tools can vary based on the specific part that requires manufacturing. Since it is computer-controlled, CNC machining can deliver superior levels of versatility, efficiency, and precision relative to other common manufacturing methods. This makes it a popular manufacturing choice for a vast range of industries and applications. Who Invented CNC Machining? Removing material using milling tools to shape an object has been an ongoing practice since ancient times. When it comes to the modern history of CNC machining thou gh, the process of controlling machine tools through numerical control was invented in 1949 by John Parsons at MIT. Development of CNC Machining In 1949, MIT conducted a research project for the US air force to use motorized methods for creating helicopter blades and aircraft engines and frames. This is what gave rise to CNC technology. Richard Kegg, in 1952, further improved the numerical control machining process, which led to CNC milling machines. Due to the absence of computers, the automated nature of early CNC machining processes was made possible with the help of punched tape. With the advent of digital computing in the 1960s, the punched tape was replaced with computerized controls. How Does CNC Machining Work? CNC machining relies on computer programs to create the layout of the process in which the machine tool should function. Since users cannot directly communicate with the machine tools, Computer-Aided Design (CAD) software is used. CAD software creates the 2-dimensional and 3-dimensional models for the required CNC machined parts. With this design, the machine knows what the final part looks like. The computerized controls do the calculation required for removing material, so the workpiece looks like the final part created in the CAD software. Let us go through the breakdown of various processes that occur during CNC machining. The Four Stages of CNC Machining CNC machining occurs in four stages: Stage 1: Creating the CAD Model Before CNC machining begins, the 2D or 3D model of the final design is required. This model is created in CAD software. There are many CAD software programs available online, free and paid. Creating CAD models is not difficult and can easily be learned. However, some complex parts might require more experience with CAD, for which expert designers can be hired. Stage 2: Converting CAD Model to CNC File No CNC machine understands CAD language directly. CNC machines only recognize movement based on coordinates. Therefore, the CAD model must be converted to a CNC understandable file called G code. Many CAD software programs can write the output file directly in G code by using the particular setting before saving the file. In other cases, converting the CAD design to G code will require dedicated software called Computer Aided Manufacturing (CAM). CAM software is a very functional tool when it comes to the automation of machine processes. Besides using CAM software, many simple free tools can convert simple CAD designs to G code with the click of a button. However, they don’t have the vast suite of features that CAM software offers. Stage 3: Configuring the CNC Machine Before starting manufacturing processes, the CNC machine must be set up the right way. Think of this as configuring the printer before you print something. You need to feed the printer with pages and check specific settings. CNC machines operate similarly. Before machining begins, there are many setup processes to complete. For instance, you must ensure the workpiece is properly positioned on the machine. The dies must also be set correctly, and other position settings. Stage 4: machining operation execution Once the configuration stage is complete, the machine operation can begin. For this, you can execute the program on the display panel of the CNC machine. Depending on what you design, you might have to go through various program prompts to choose different types of settings and options. Once the CNC program is executed, the machine keeps going till the end of the program. It only stops if switched off by the operator or in the case of an unexpected error or power disruption. Main Terminologies in CNC Machining It is crucial to be familiar with CNC machining terminology in this field. Some common CNC-related terms include: Computer-Aided Design (CAD) Computer-Aided Design is the software that creates the graphic representation of the required final part in 2D or 3D. Generally, complex parts are produced by breaking them into small parts, each having its own CAD model. AutoCAD and FreeCAD are two of the most popular CAD applications, with the latter being completely free. Computer-Aided Manufacturing (CAM) Computer Aided Manufacturing (CAM) software generates CNC programs that a machine can understand. These programs help automate different types of machines, including CNC machines. CAM software works together with CAD programs to execute operations using a CNC machine. Most quality CNC machines come with complementary CAM software. Distributed Numerical Control (DNC) In a Distributed Numerical Control (DNC) setup, multiple machine tools can be connected to a central server. The central server processes the design files and sends commands to each machine tool separately. DNC is utilized when the individual CNC machine memory is too small to process the software. It can also be used where multiple numerical control machines require synchronized working for faster operational capabilities. Manufacturing Data Collection (MDC) Manufacturing Data Collection (MDC) is what it sounds like. Manufacturing Data Collection software collects data from machines and operators about the different manufacturing information generated in real time. This information helps manufacturers to improvise on the existing production line. It also points out the causes of any delays and loss in production. What are G-code and M-code? G-code and M-code are files that a CNC machine requires to operate. Each of these has its own importance, which we will go through one by one: G-code The ‘G’ in G-code refers to Geometry, making G-code a Geometric code. G-code is an alphanumeric command that tells the CNC machine how to move. The X , Y , and Z references in G-code refer to the axes of movement, and the number pertains to the value in that particular axis. N refers to the line number. Some particular codes refer to specific operational capabilities of the machine, such as adjusting the spindle speed or turning the spindle on and off. M-Code M-codes are miscellaneous machine codes that perform the non-cutting actions of the CNC machine. These include starting and stopping different programs, controlling the coolant flow, or adjusting the behavior of machining tools. What are the Different Types of CNC Machining Processes? A CNC machine is not one specific machine, as it is a group o f different types of CNC machines working on various machining processes. Some of the most popular CNC machining operations include: CNC Milling CNC milling is one of the most popular types of CNC machining processes. In fact, many professional machine shops often use a CNC machining and CNC milling process interchangeably. Face milling and peripheral milling are two of the most frequently used CNC mill applications. In a CNC milling machine, rotating cutting tools move relative to the workpiece to remove material. The cutting tool (also called a milling tool) is fixed on a spindle that can rotate. The rotation and movement of the spindle give CNC milling machines the ability to perform three or more axes milling operations. CNC Drilling The CNC drilling process is a lot simpler than using milling tools or the turning process. In CNC drilling, the workpiece is held stationary while a drill bit moves over the workpiece and creates holes. The purpose of drilling holes might be to add screw bolts, aesthetic requirements, or any other use. CNC Grinding CNC grinding machines use a rotating flat abrasive wheel for removing material from rough workpiece surfaces. This machine process is usually applied to create a smooth-finished part. The grinding wheel rotates at a very high speed. CNC Routing CNC routers are very similar to CNC milling machines. The main difference is that in a CNC router, the workpiece is always stationary, and the cutting tool moves in X, Y, and Z dimensions. CNC routers create faster cuts than milling machines without compromising accuracy and design complexity. Other Types of CNC Machines and CNC Operations Besides the various types mentioned above, there are other CNC processes too. Some independent fabrication machines are integrated with a CNC for automatic movement. Some of these additional CNC machines are: Broaching Broaching utilizes a toothed cutting head to create niche shapes on a workpiece. Broaching cuts are very consistent and highly accurate. These machines can be linear or rotary (with a rotating toothed cutting tool). Sawing Sawing utilizes a toothed blade for creating straight, linear cuts. The cuts are created by the removal of material due to friction with the saw blade. When operated with a CNC, this process is usually applied for the automated cutting of materials. Honing Honing is similar to grinding in that it is generally used for the secondary finishing of a material. In the honing process, an abrasive stone or wheel is used for controlled grinding of the workpiece, creating the desired shape, size, or finishing. Lapping Lapping is also similar to grinding. But, lapping uses an abrasive paste, powder, or mixture instead of a grinding wheel to create a smooth surface finish. The abrasive mixture is inserted between two materials (one of which is the workpiece) and then rubbed against each other. CNC lathes CNC lathes are primary shaping tools used for machining metal or wood. In a lathe machine, the workpiece is rotated around a central axis, and the machining head moves linearly along the surface. CNC lathes can perform various functions, such as cutting, drilling, sanding, knurling, facing, and more. CNC lathes perform much better than manual lathes. Plasma Cutters Plasma cutters are an evolved form of cutting technology, using a high-temperature plasma jet to cut material. The plasma is created by an electrical arc, so this method applies to conductive materials only. Laser Cutters Laser cutters use a laser beam to cut through a material. Unlike plasma cutting, laser cutting is not limited to the cutting of electrically conductive materials. Laser beams can cut through anything by adjusting the laser parameters. Flame Cutters Flame cutting uses an Oxy-acetylene (also known as Oxy-fuel) gaseous mixture to cut through metals. When the Oxy-fuel stream is narrowed and ignited, it creates an ultra-high temperature flame that can easily cut through metal. Press Brakes The purpose of Press Brakes is to bend metal plates and sheets. The material is placed between a V-shape or a U-shape die. Then the die is pressed, resulting in the bend as required. Electric Discharge Machines (EDM) Electrical Discharge Machines (EDMs) are used for cutting conductive materials. In EDM, electrical pulses are emitted by a cutting head near the material, which creates an electrical arc. This arc melts and removes the material at the required position resulting in a cut. Water Jet Cutters Waterjet cutters utilize ultra high-pressure water for the cutting action. These cutters can cut through anything: metal, alloy, wood, stone, or glass. The water jet stream is controlled by CNC and moved according to the software. Vertical CNC Machining Horizontal CNC Machining CNC Turning Precision Wire EDM Metal Machining Plastic Machining Selecting the right CNC machine for the job When making CNC machined parts, it is important to figure out which type of machine is most suitable for the parts in question. Every machine has its pros and cons, but it is difficult to find every kind of CNC machine in one place — except maybe at a machine trade show, or in a CNC shop willing to invest lots of money. If the most suitable machine is not available, you need to find a way to make the parts with the machines that are available. Here are some explanations o f vertical vs horizontal milling and turning machines . Figuring out the best way to load the workpieces When you have chosen the CNC machine to make your parts, the next step — before programing — is to find the best way to load your workpieces in order to gain the best machined result. I believe this stage is more important than making the tool paths, but in my experience, most machinists have a difficult time with it, and it prevents them from moving forward smoothly. As a prototype machining company, we try to hire people who have an open mind and are able to find solutions in this area, since we come across di fferent CNC parts every day. (Of course, some people quit the job within two weeks!) Check out the different CNC workholding methods . Knowing what type of cutting tool to use After choosing the machines and deciding on the best way to make the parts, selecting the right cutting tools will help to achieve a tighter tolerance and better surface finish. In short, suitable cutting tools result in better components. Here’s an example: milling ribs with draft might take hours using normal sphere cutting tools, but would require just a few minutes with a taper cutter. So imagine how much time you could save when milling 10 pieces or more. Find out the differences between types of CNC cutting and machining tools . What are the Advantages of CNC Machining? CNC machining technologies have revolutionized the manufacturing industry by minimizing manual work and allowing for unparalleled levels of consistency and accuracy. It is often considered a modern boon due to its numerous advantages. As a product designer, it is vitally important to know whether to stick with CNC machining or to design the parts for another manufacturing process. Here is a brief overview of some of the key benefits: Production Speed Production speed is one of the primary reasons which led to the vast and rapid spread of CNC machining. With CNC machining, it is possible to speed up production exponentially since it removes the limitations of human labor. Consistency Computer Numerical Control machining ensures that all the parts created look and work the same. There is no possibility of human error. This leads to the fabrication of precision parts that serve their purpose as intended. Reduction of Rejections In conventional manufacturing processes using manual labor, there was a lot of human error, which resulted in rejections during quality control. This wasted a lot of time and resources. With CNC machining, the whole process is automated, which leads to fewer rejections. Cost Saving Labor costs include the salary paid to the labor, downtime during breaks, and the added benefits payments. The accuracy, speed, efficiency, and automation of CNC machining reduce manufacturing costs by minimizing production times and labor hours. These savings can be passed along to customers, creating a competitive advantage and providing an opportunity for business reinvestme nt. However, other factors affect CNC machining costs , like quantity, material selection, and geometry. Material Versatility CNC machining can be performed on practically any material with sufficient hardness. Manufacturing Data Tracking A CNC machine feeds manufacturing data that allows manufacturers to track the entire process for every part. They can learn about the exact machines every part went through during manufacturing. In case of a fault, the exact cause can be tracked immediately. Accuracy With CNC machining, it is possible to achieve accuracy on a micro level. Manufacturers can even push that limit with appropriate tools. Such a level of accuracy is not possible with manual operations. Read o ur detailed article covering the benefits of CNC machining for a deep dive into all its advantages. What Materials Can Be Processed By CNC Machines? CNC machining enables working on a wide range of materials. In fact, you do not need various machines for CNC machining materials that are different. Most types of CNC machines support multiple materials allowing them to switch between producing different machine parts with a slight change of tooling. Metals Metal is one of the most common materials that undergo the CNC machining process. Its hardness makes using manually controlled machining long, arduous, and less precise. CNC machines provide the best and fastest way to work on metal parts. Some of the metals that are used to manufacture parts with CNC machines are: Aluminum: Aluminum is not just the most abundant metal on earth but also the most commonly used in CNC machining. Its high strength-to-weight ratio makes it ideal for lightweight parts that require decent strength. Magnesium: Magnesium is most commonly utilized for creating the outer body of electronics. This is because Magnesium is 33% lighter than Aluminum, making it perfect for reducing the weight of electronics like laptops. Titanium: Titanium is one of the toughest materials out there. It undergoes CNC machining for applications in aerospace, the military, and for any other high-grade requirement. Cast Iron: CNC machining parts from cast iron is very useful as you can produce parts at twice the speed of producing parts using steel, with less wear resistance on tools. Alloys CNC machines can work on metal alloys just as well as metals. Here are the common alloys that go through CNC machining: Stainless Steel: Stainless Steel is one of the more popular varieties of steel. Due to its hardness and other physical properties, it is always shaped by the CNC machining process. Carbon Steel: Carbon steel is the most widely used alloy in the world. It is cheaper than stainless steel and has higher strength. CNC machines can shape carbon steel with high accuracy. Brass: Brass is soft and corrosion-resistant. There are numerous varieties of brass with varying proportions of zinc and copper. All these varieties can be CNC machined. Plastic Many people are unaware of it, but CNC machining can also be used to shape plastic parts. Common plastics used in modern manufacturing include: Nylon: Nylon is strong, flexible, and fire-resistant. Nylon CNC machined parts are sometimes used to replace some metal parts since Nylon also has good lubrication properties. ABS: ABS plastics are often used for applications like injection molding due to their thermoplastic nature. However, for making prototypes, CNC machining ABS is the better way to go. PMAA: PMAA Acrylic is strong, transparent plastic. Therefore, PMAA is used for replacing glass in items like optical equipment or food containers. PEEK: PEEK is one of the most expensive plastics with exceptional temperature resistance and physical properties. CNC machining of PEEK finds applications in the aerospace and medical industries. Wood Wood is another common material used in CNC machining. Not only that, it is actually quite easy to machine due to its soft nature. The most common application is for making furniture. What are the Applications of CNC Machining? CNC machining has applications in every in dustry, from the creation of tools to the final end product. Here’s an overview of some of the use cases of the CNC machining process: Vehicles: CNC machining is utilized for making the frames, engines, and other small components of all types of transport vehicles, including cars, trains, and airplanes. Metal Fabrication: The metal fabrication industry relies on CNC tools for all types of projects. Electronics: The electronics industry also uses CNC machining for making appliance frames. Research and Development: Since CNC machining can create anything based on a 2D or 3D digital model, it is the go-to method for making prototypes. Defense: High-end CNC machines are used for heavy-duty defense operations, such as creating weapons, aircraft, and more. Architecture: CNC machining is also used for creating art and decor pieces. For instance, the intricate stonework you see in kitchens is made using CNC-controlled waterjet cutting tools. Robotics/automation : CNC machining allows for rapid prototyping with the ability to make quick and frequent modifications and sophisticated robotic parts, which are essential for success in the fast-growing and innovative robotics field. Medical : CNC machining benefits the fast-paced medical device sector by enabling rapid prototyping for product testing and validation. It also delivers high-quality end-use components that are utilized in everything from orthotic devices to MRI machines. How Does CNC Machining Compare to Other Machining Methods? The only practical alternative to CNC machining is machining done by hands. Of course, CNC machining is leaps and bounds ahead of any manual method. Some of the points to consider abou t CNC machining vs. manual machining are: Industries nowadays follow a manufacturing process suitable to meet the large-scale demand. With CNC machining, this demand can be fulfilled effectively. In contrast, manual production methods cannot produce parts at the required rate. By using CNC machines instead, physical labor can be dedicated to more crucial and intellectual tasks. CNC machines eliminate the human error factor that is present in manual machining. This leads to better utilization of resources by lowering the number of defective pieces. There are many tasks that manual machining cannot accomplish due to human physical limitations, such as working on extremely hard materials. CNC machining can complete such tasks with ease. With CNC machining, there is no downtime due to lunch breaks or shift changes. Additionally, production can run 24/7, which increases productivity by a huge factor. Are CNC machines hard to operate? Every type of CNC machine has its own operating instructions. Generally, CNC machines are easy to operate and do not require the operator to undergo a technical course to use them. In fact, you can create basic parts after a few hours of tutorial videos, which are abundant online. If you want to be a pro at CNC machining, spend some time learning the designing part to create CAD drawings. Once you know how to create technical drawings and write efficient digital programming code, you can optimize the existing manufacturing process used by a CNC machine. Is CNC a Good Career? Yes, CNC is a rewarding career not only in terms of monetary remuneration but also in terms of job satisfaction. CNC operators use their minds on real-world problem-solving to create productive and innovative equipment. Is CNC in High Demand? Since CNC machines have taken over the manufacturing process in most sectors, CNC operators are indeed in huge demand nowadays. CNC Machining Market Overview The CNC machining market is expected to reach a valuation of over $128 billion by 2028, accordi ng to a Fortune report . The major driving factor in this growth rate will be the increased demand for semiconductors, the use of CNC for making medical equipment, and the rise of EV vehicles. Challenges in the CNC Industry The CNC industry has established a dominance that isn’t going to fade in the next few decades. Not until a new technological revolution comes along. Even so, there are a couple of challenges in the industry that could be problematic. For one thing, CNC machining is not very customization friendly. It is possible to create custom pieces, but it requires going through the whole process all over again. Making slight changes to the final products involves alterations to the CAD files in the first stage. Another challenge comes when we talk about making complex parts. There are machines available now that have the additional axes required to make complex parts. But many manufacturers are still using CNC machines with limited freedom of movement. Phasing out the old machines to incorporate the new, high-end CNC machines with better features could be challenging. What are the Trends in the CNC Machining Industry? The main trends present in the CNC industry are: Development of more axes to create the most complex geometries possible Increased use of robotics to make the entire process automated Development in CAD and CAM programming language for utilization of newer features Increased workability on the nanoscale for use in semiconductor applications Key Takeaways CNC machining technology is the pillar on which modern manufacturing stands. The CNC machining process begins with the most basic raw materials, turning them into anything the mind wishes. The technology is so powerful that it turns metal sheets into aircraft fuselages, automobile bodies, and metal bars into the axles that those automobiles run on. CNC machine tools are the go-to option, whether you require prototypes, small-scale sample production, or large-scale production runs. The best thing is that you don’t even have to own any CNC machining equipment to get the benefits of the process. Start Your CNC Project Today CHICTAO is a precision CNC machining and CNC prototyping company with capabilities including milling, turning, wire EDM, aluminum machining, and more. Our skilled machining experts combined with our 3-, 4-, and 5-axis CNC machining capabilities allow us to achieve exceptional levels of precision, quality, and complexity for even the most complex or critical applications. With years of experience in our field, we have the expertise to provide comprehensive precision machining services that meet the standards of myriad industries.

By CH

•

September 5, 2024

Key words: automatic CNC machining parts, CNC machining products, CNC machining service, China CNC processing service What is CNC Machining? When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot. In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously. The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program. With a numerical control machine, programs are inputted via punch cards. By contrast, the programs for CNC machines are fed to computers through small keyboards. CNC programming is retained in a computer’s memory. The code itself is written and edited by programmers. Therefore, CNC systems offer far more expansive computational capacity. Best of all, CNC systems are by no means static since newer prompts can be added to pre-existing programs through revised code. CNC Machine Programming In CNC manufacturing, machines are operated via numerical control, wherein a software program is designated to control an object. The language behind CNC machining is alternately referred to as G-code, and it’s written to control the various behaviors of a corresponding machine, such as the speed, feed rate and coordination. Basically, CNC machining makes it possible to pre-program the speed and position of machine tool functions and run them via software in repetitive, predictable cycles, all with little involvement from human operators. In the CNC machining process, a 2D or 3D CAD drawing is conceived, which is then translated to computer code for the CNC system to execute. After the program is inputted, the operator gives it a trial run to ensure no mistakes are present in the coding. Due to these capabilities, the process has been adopted across all corners of the manufacturing sector, and CNC manufacturing is especially vital in the areas of metal and plastic production. Find out more about the types of machining systems used and how CNC machine programming fully automates CNC manufacturing below: Open/Closed-Loop Machining Systems During the CNC manufacturing process, position control is determined through an open-loop or closed-loop system. With the former, the signaling runs in a single direction between the CNC controller and motor. With a closed-loop system, the controller is capable of receiving feedback, which makes error correction possible. Thus, a closed-loop system can rectify irregularities in velocity and position. In CNC machining, movement is usually directed across X and Y axes. The tool, in turn, is positioned and guided via stepper or servo motors, which replicate exact movements as determined by the G-code. If the force and speed are minimal, the process can be run via open-loop control. For everything else, closed-loop control is necessary to ensure the speed, consistency and accuracy required for industrial applications, such as metalwork. CNC Machining Is Fully Automated In today’s CNC protocols, the production of parts via pre-programmed software is mostly automated. The dimensions for a given part are set into place with computer-aided design (CAD) software and then converted into an actual finished product with computer-aided manufacturing (CAM) software. Any given workpiece could necessitate a variety of machine tools, such as drills and cutters. In order to accommodate these needs, many of today’s machines combine several different functions into one cell. Alternately, an installation might consist of several machines and a set of robotic hands that transfer parts from one application to another, but with everything controlled by the same program. Regardless of the setup, the CNC fabrication process allows for consistency in parts production that would be difficult, if not impossible, to replicate manually.

By WL

•

September 5, 2024

We boast dozens of 5-axis laser cutting machines, which enable us to produce better parts for our client within their expected timeline. Automatic CNC machining parts are produced with the most up-to-date processing centers. Laser cutting has many advantages, including: Precision Laser cutting can produce cuts with a margin of error of +/-0.1 mm, which is more accurate than other cutting methods. Consistency Laser cutting maintains quality every time, and the edges are sealed so there's no fraying. Versatility A single laser cutter can perform the work of multiple traditional cutting machines, including cutting, drilling, and etching. Automation Laser cutting machines are controlled by CNCs, which means that parts and products have little to no variation and fewer defects. Energy efficiency Laser cutting is more energy efficient than many other cutting methods because it operates at fast speeds. Material compatibility Laser cutting can be used on almost all materials, especially fine grain steels, stainless steels, and other structural and wear resistant steels. Minimal waste Laser cutting uses more sheets and leaves less waste, which means that a higher percentage of the sheet material can be used. Burr-free parts Laser cutting produces burr-free parts.

All copyright reserved @ Shenzhen ChicTao Trading Co., Ltd.

Powered by WL Co.