We are a Shenzhen-based versatile solution supplier for small batch customized parts.

ChicTao

is a leading machining parts supplier in China. It strives to provide our customers with industrial products and parts with high precision, high developing efficiency, fast market response, short developing time, and affordable cost solutions.

Laser Cutting

Our versatile laser cutting machines are capable of doing almost all kinds of solid materials in various shapes.

CNC Machining

CNC machines can do most of the jobs that laser cutting machines can, but due to a wider variety of cutting molds, they are still irreplaceable. And they are also capable of doing the same materials.

3D Printing

3D printing allows for quick design, development, and testing of custom parts. Design changes can be made without affecting manufacturing speed.

UV Printing

UV printing can be used on a variety of materials, including paper, glass, plastic, PVC, acrylic, and polycarbonate.

UV printing produces a more vibrant finish because the UV light doesn't give the ink time to soak into the material.

Welding

Laser welding is highly accurate and can weld small parts without damaging them.

Laser welding can join material combinations that other methods can't.

Coating

We boast the most up-to-date automatic powder-coating lines and spray painting lines, which enable us to coat various materials.

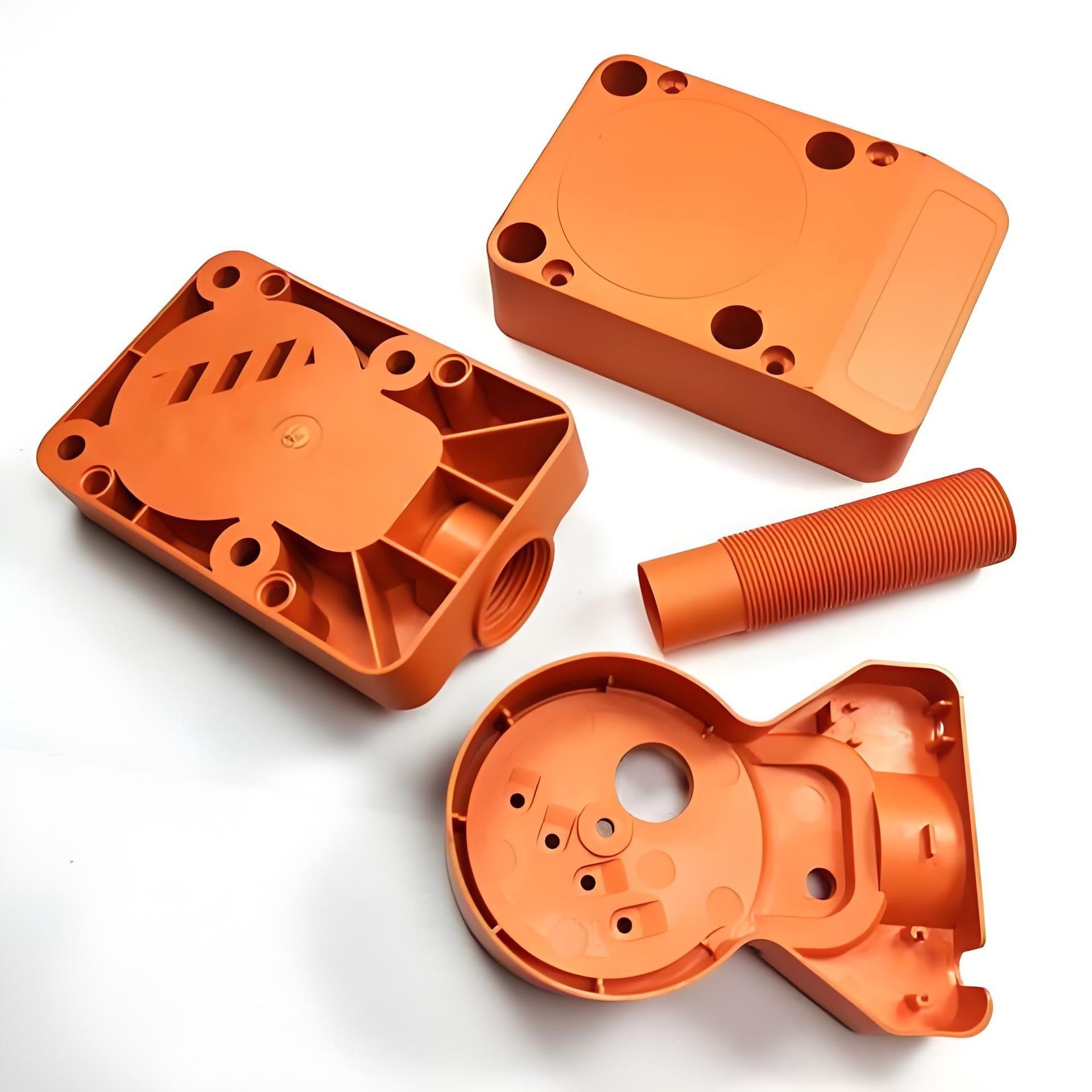

Silicone Molding

Silicone can operate normally in a wide temperature range, from minus 100°C to plus 250°C (212° to 482°F).

Silicone molds are durable and can withstand high heat and cold. They are resistant to tears, warps, fading, and degradation and can be used repeatedly.